αGEL Products

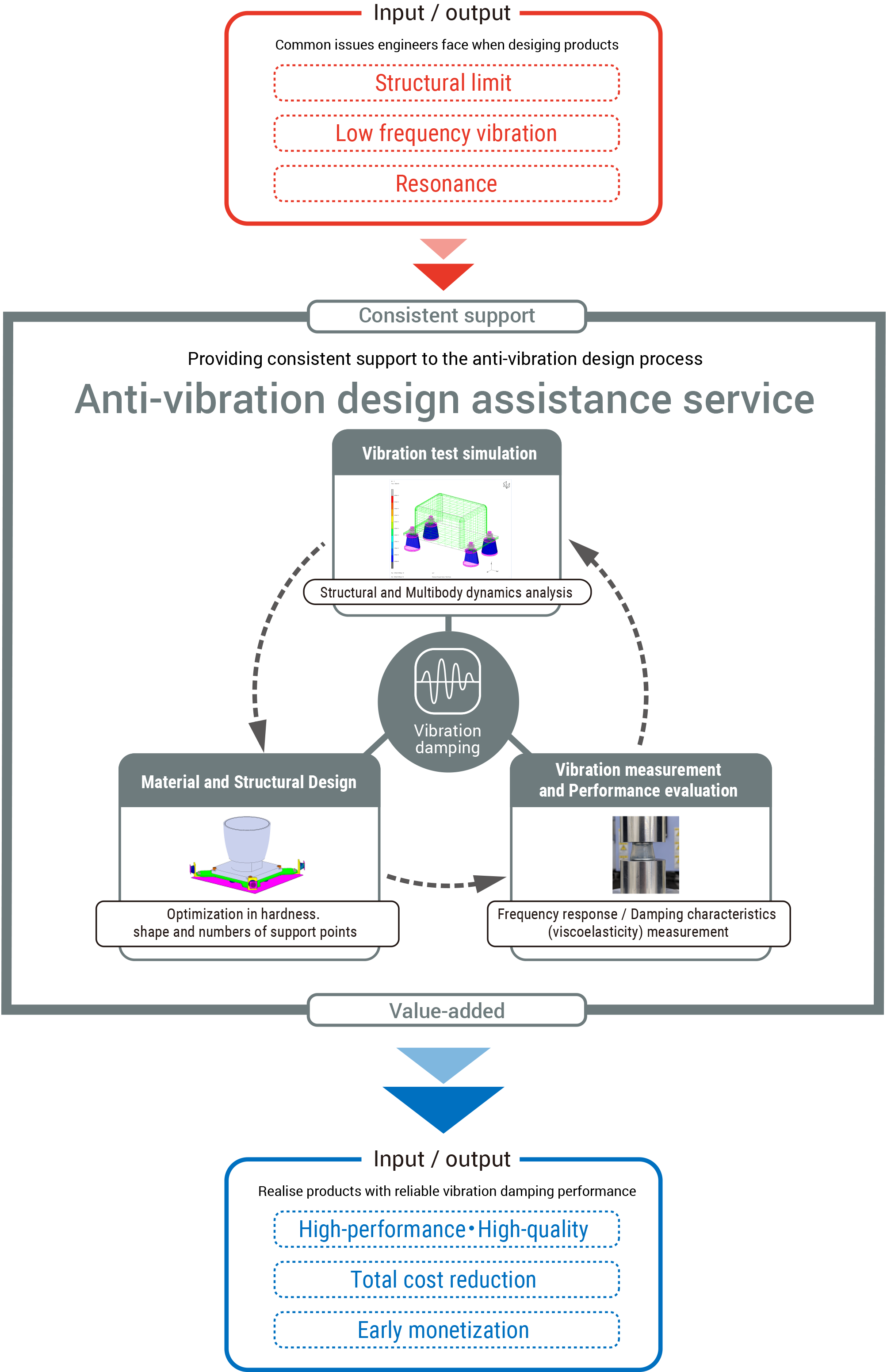

Anti-vibration design

assistance service

assistance service

- Providing the best-in-class solutions with the reliable design approach by the vibration isolation experts

- αGEL provides total support for the anti-vibration design process, which is indispensable for ensuring product quality and improving durability, with its know-how based on the knowledge and experience we have accumulated over the years, as well as its flexible conceptualization and technical capabilities to create new materials.

We provide value-added solutions that contribute to the realization of high-performance, high-quality products and to the reduction of development costs. -

- Have you ever faced challenges or issues

in vibration isolation design like below? - 【Click to see solutions and case studies.】

Service details

As a development partner for vibration isolation design, we provide total support for vibration test simulation, material and structural design, vibration measurement and performance evaluation.

We invite you to utilize the knowledge and technical know-how we have accumulated over the years in vibration isolation for your product development.

Vibration test simulation

We provide vibration analysis and prediction using Finite Element Analysis (FEA).

The analysis of how αGEL will provide damping performance against expected vibrations can be performed considering the material, shape, and location of where installed.

In addition to analysis of the damping material alone, coupled analysis of the mechanism and structure of the product as a whole is also available, allowing us to understand how to design the product to achieve the target vibration dampening performance.

- Structural analysis simulation

-

Structural analysis is a method of calculating and quantitatively analyzing deformation and stress when loads are applied to a modeled structure.

To achieve the required vibration isolation performance, we perform an analysis that quantitatively demonstrates the optimal physical properties of αGEL. -

<Supported Menu>

- ・Behavioral analysis with geometry changes

- ・Analysis of horizontal and vertical stresses

- ・Strain Analysis

-

See case studies

on Structural analysis simulation

●Behavioral analysis with geometry changes

Compression properties of various shapes can be simulated. It is also possible to simulate αGEL with accessories attached such as springs and metals.

●Analysis of horizontal and vertical stresses

We can simulate how αGEL behaves under various external stresses, for example, horizontal and vertical.

●Strain Analysis

We can analyze the strain distribution inside the αGEL when the axis is eccentric.

Close case studies

Close case studies

- Multibody dynamics analysis simulation

-

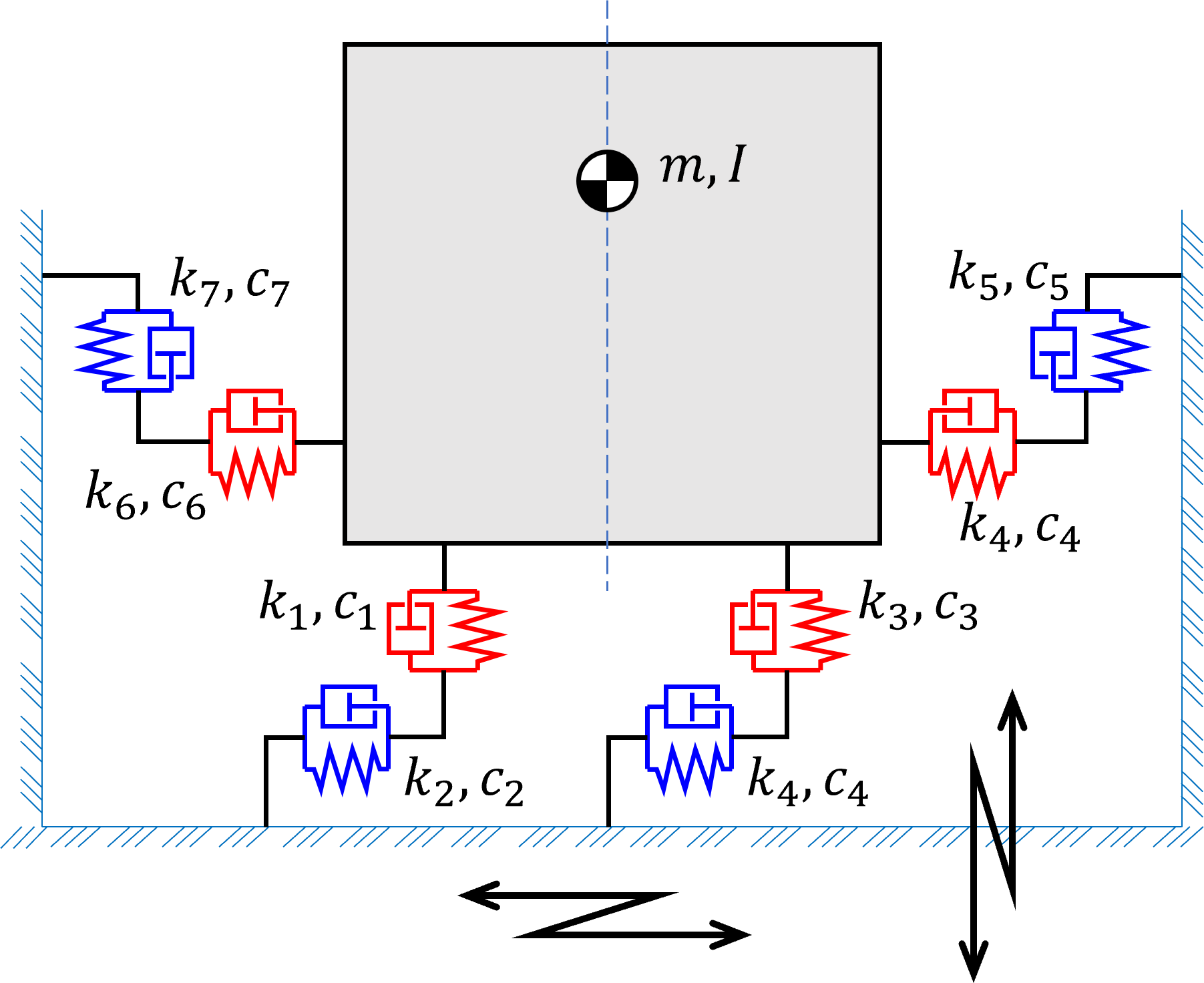

Multibody dynamics analysis is a method of analyzing the interaction and positional relationship of each component in a multi-component model based on the equations of motion (position, velocity, acceleration, etc.).

The structure of peripheral components and vibration dampers can be modeled to predict and evaluate their response to target vibrations. -

<Supported Menu>

- ・Analysis of vibration isolating trestle

- ・Analysis of vibration isolating characteristics according to the quantity of vibration dampers

- ・Analysis of vibration isolating characteristics according to the mounting position of the vibration dampers

- ・Analysis on vibration response of eccentric center-of-gravity model

(analysis of vibration isolating performance by center-of-gravity position)

-

See case studies

on Multibody dynamics

analysis simulation

●Analysis of vibration isolating trestle

Simulation can be performed considering not only the vibration damper alone, but also the entire vibration isolating trestles.

Analysis is also possible when the vibration damper is installed not only in the vertical direction, but also in the horizontal (shear) direction.

●Analysis of vibration isolating characteristics according to the quantity of vibration dampers

It is possible to analyze the vibration isolating characteristics when the number of installed vibration dampers is increased or decreased.

●Analysis of vibration isolating characteristics according to the mounting position of the vibration dampers

Prediction and analysis can be performed according to the mounting position of the vibration dampers, such as a pattern pinched from the top and bottom directions.

●Analysis on vibration response of eccentric center-of-gravity model

(analysis of vibration isolating performance by center-of-gravity position)Analysis focusing on the position of the center of gravity, one of the most important factors in vibration isolation design, is available.

Close case studies

Close case studies

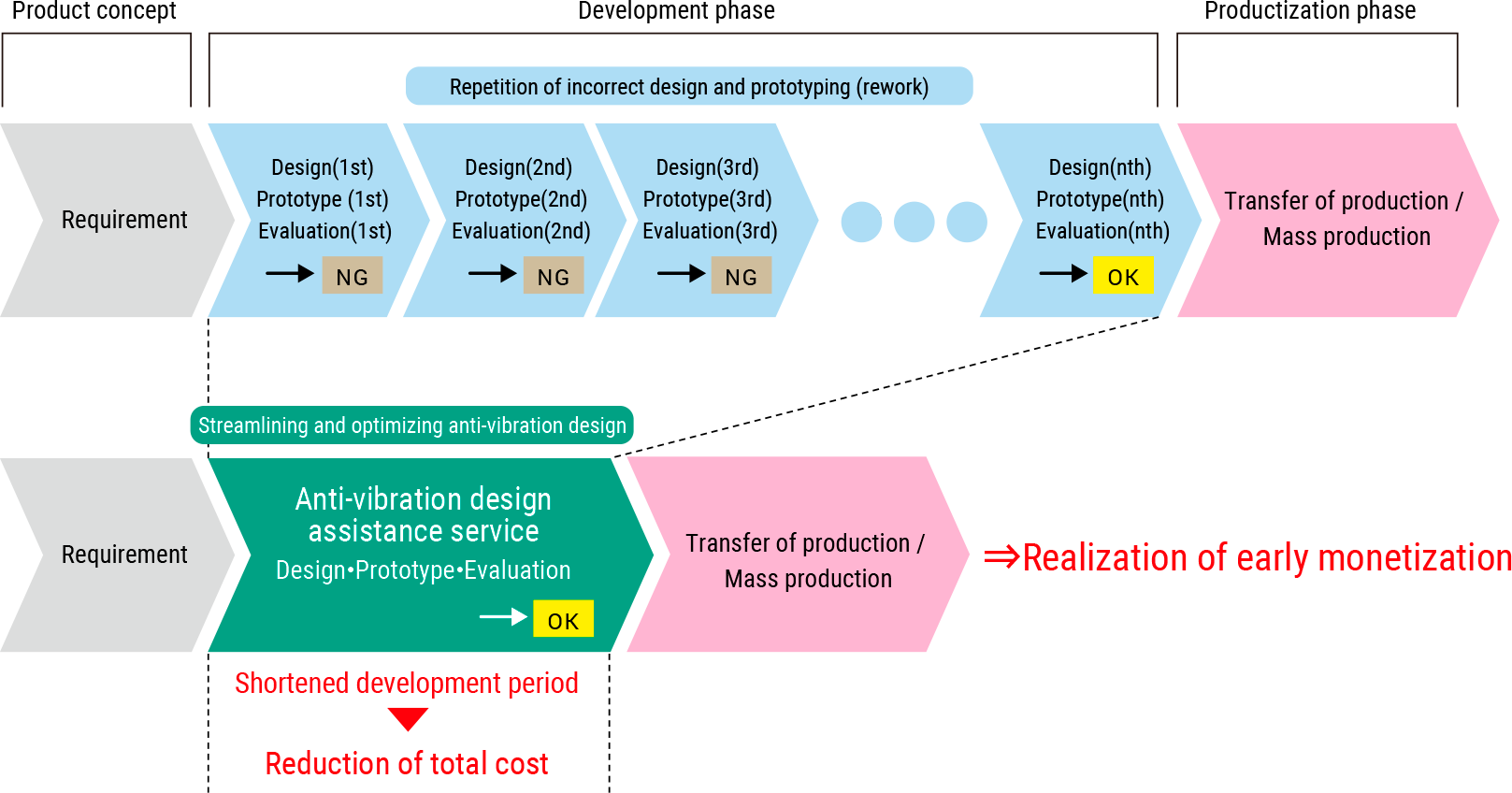

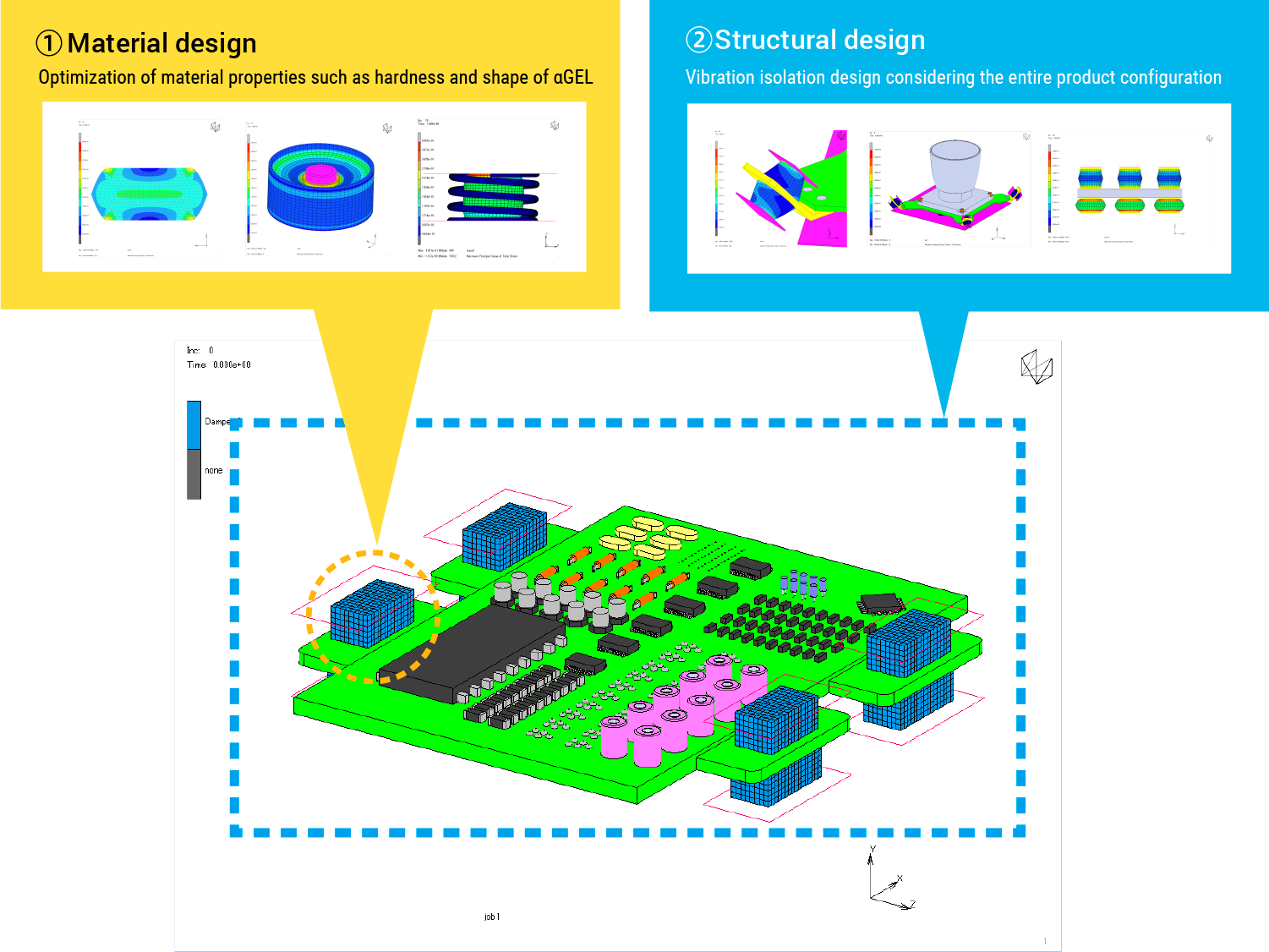

Material and Structural Design

The softness and damping characteristics of αGEL and the shape of the damper can be optimally designed for the vibration to be counteracted.

We can also design the entire structure, including the mounting points and number of αGEL dampers, and the combination of αGELs with other components.

- Material design

-

Customization of hardness, damping characteristics, product shape, etc. are available.

-

<Supported Menu>

- ・Shape design of αGEL

- ・Hardness design of αGEL

- ・Damping characteristics design of αGEL

-

See case studies on Material design

●Shape design of αGEL

αGEL and peripheral components (springs, metal fittings, etc.) can be optimally designed for shape.

●Hardness design of αGEL

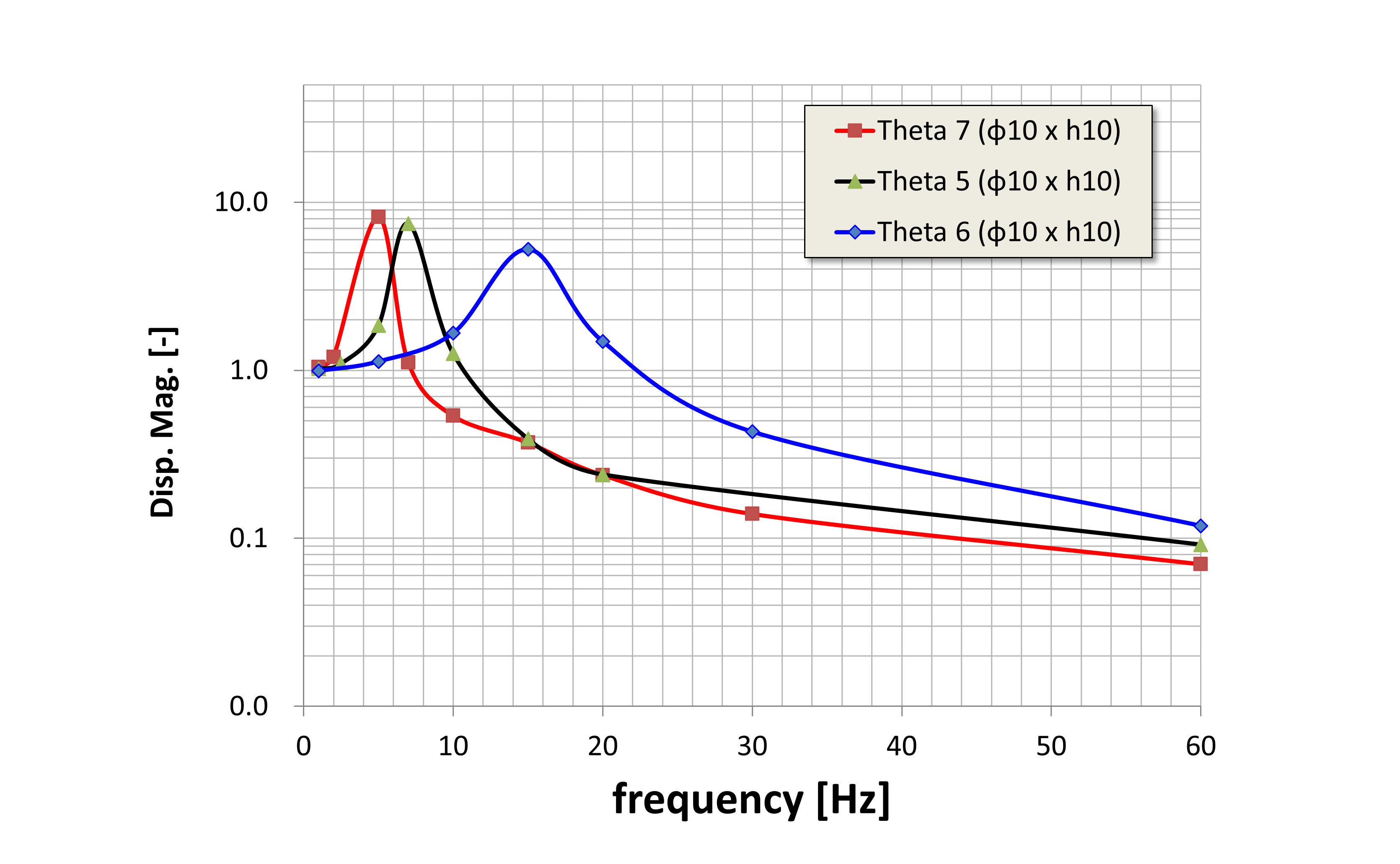

Optimal hardness design is available by analyzing the vibration isolating characteristics by changing hardness in the same geometry.

●Damping characteristics design of αGEL

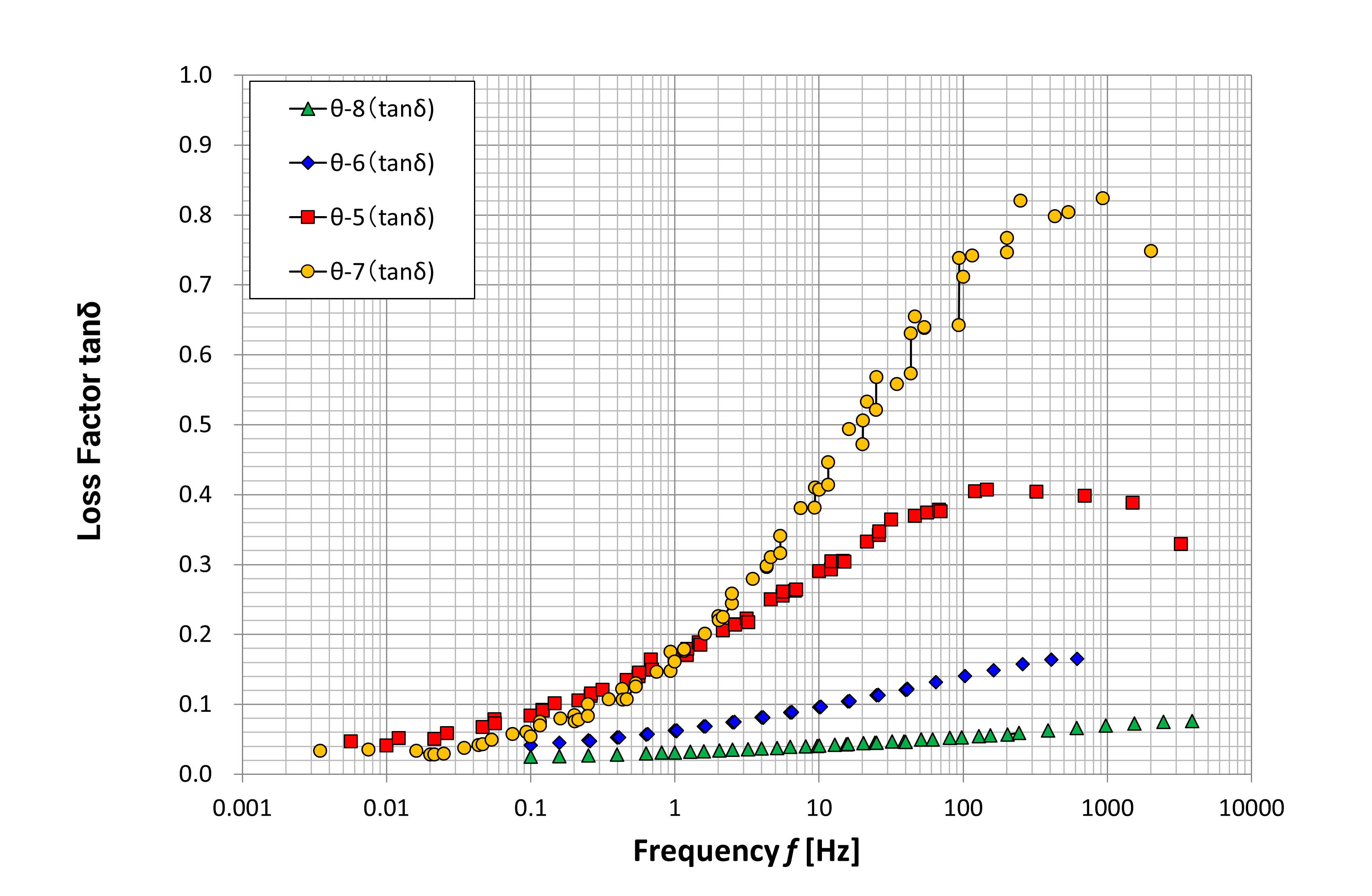

The damping characteristics of αGEL dampers are analyzed for each frequency band, enabling the optimal design of αGEL dampers for anti-vibration design.

Close case studies

Close case studies

- Structural design

-

We can design not only the vibration damper for the vibration to be addressed, but also the structural design including the surrounding components.

-

<Supported Menu>

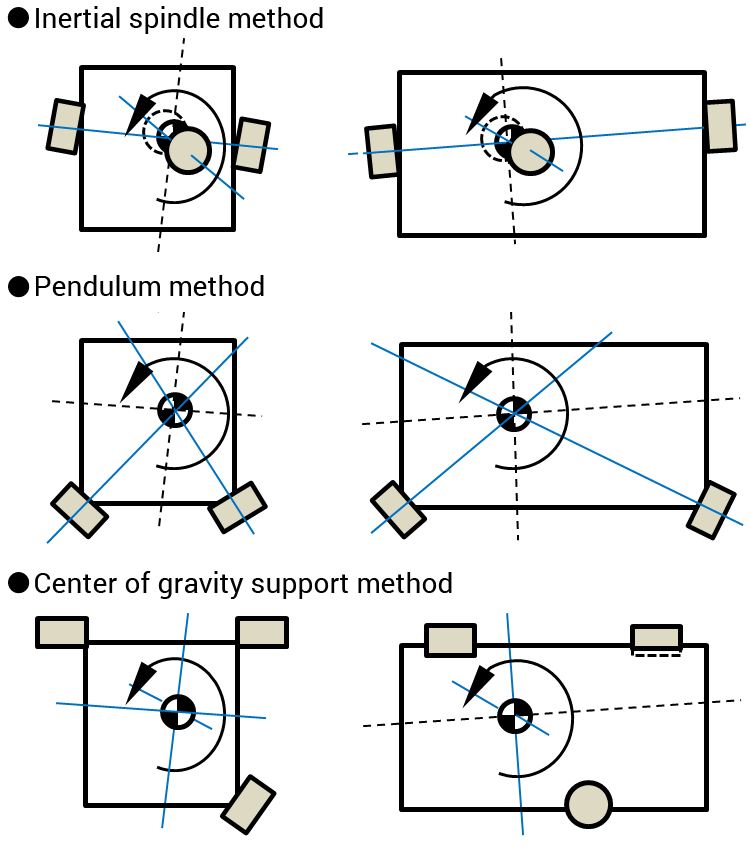

- ・Design of anti-vibration mount system (vibration isolation material mounting system)

- ・Design of vibration isolating structures (type and shape)

-

See case studies on Structural design

●Design of anti-vibration mount system (vibration isolation material mounting system)

Designs can be made by selecting the optimum method from among various types of vibration isolation methods.

●Design of vibration isolating structures (type and shape)

We can design not only the mounting position of the vibration damper, but also the optimum type and shape of the material.

Close case studies

Close case studies

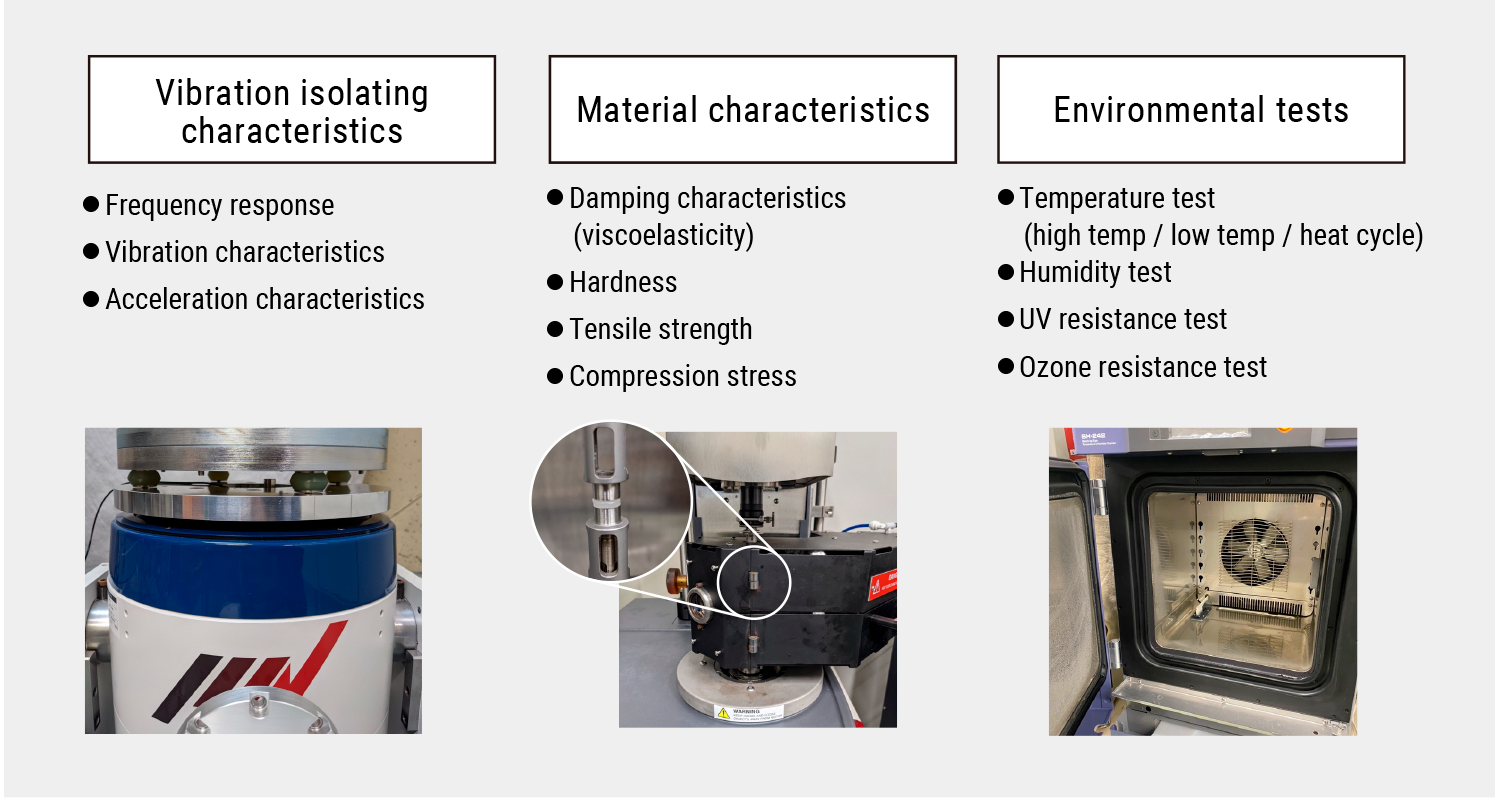

Vibration measurement and Performance evaluation

Various measurements such as reproducibility tests, vibration measurenments and performance evaluations are available.

We can flexibly respond to customer needs and provide total support for anti-vibration design by using the data obtained from these measurements for vibration test simulation and material and structural design.

- Vibration measurement and Performance evaluation

-

<Supported Menu>

- ・Measurement of vibration isolating characteristics

- ・Measurement of hardness

- ・Damping characteristics (viscoelasticity) measurement

- ・Tensile strength and compressive stress measurements

- ・Environmental tests

-

See case studies

on Vibration measurement

and Performance evaluation

●Measurement of vibration isolating characteristics

Vibration isolating characteristics can be measured using a shaking table.

●Measurement of hardness

Hardness can be measured by the most appropriate method, such as needle penetration, Asker-C, etc.

●Damping characteristics (viscoelasticity) measurement

Damping characteristics can be measured with variable frequency and temperature.

●Tensile strength and compressive stress measurements

Material strength measurement is available.

●Environmental tests

Environmental tests such as high/low temperature, high humidity, heat cycle, and ozone/UV exposure are available.

Close case studies

Close case studies

Benefits and Features

We provide total development support from the initial stage of the anti-vibration design process, "vibration test simulation", to the final stage, "vibration measurement and performance evaluation" including "material and structural design".

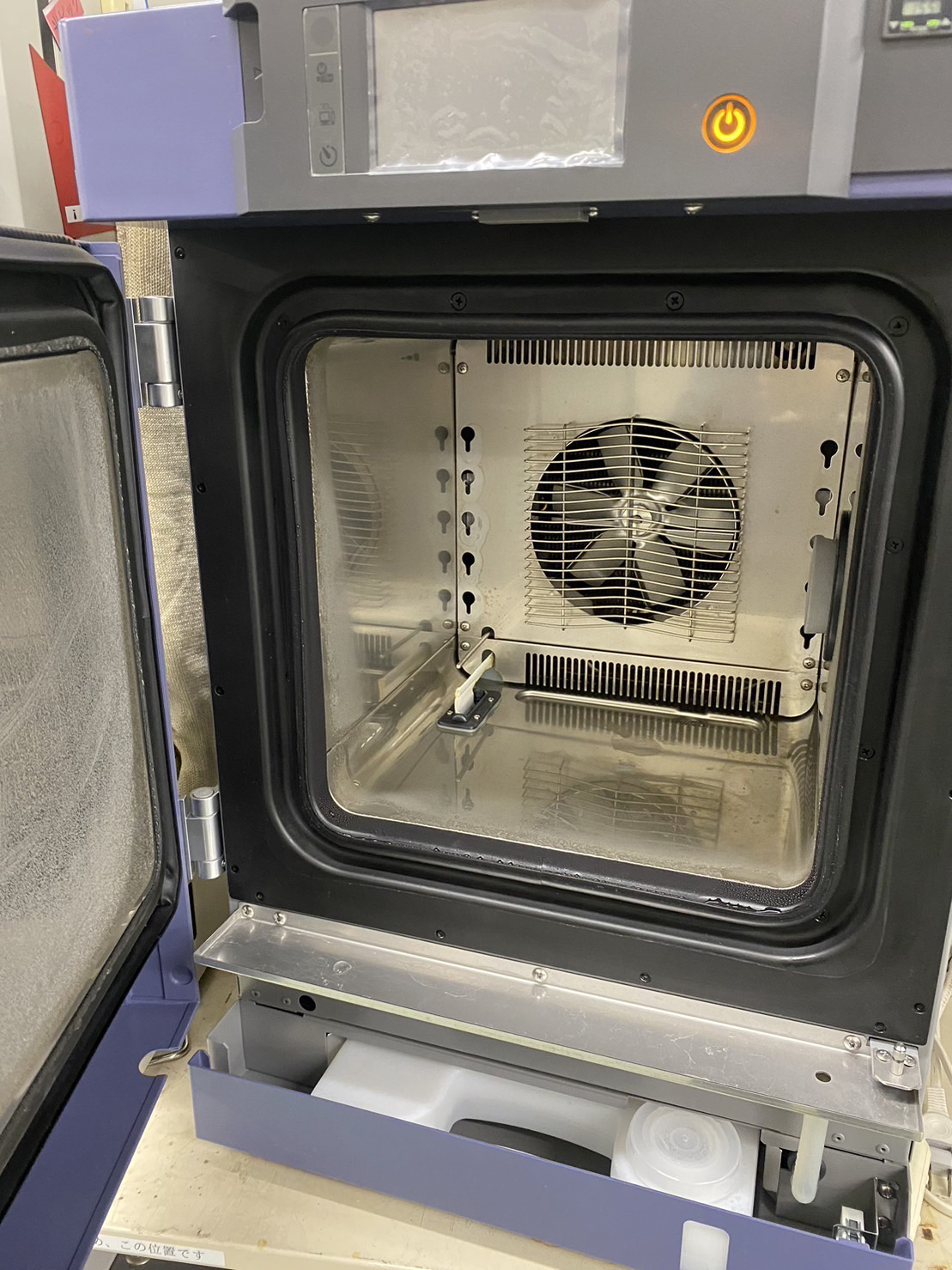

【Vibration test simulation】

- ・Reduce reworks (errors in the design stage and repeated verification of prototypes on actual equipment) that occurs during conventional verification, thereby reducing total development costs (both cost and time).

Contributes to early monetization by shortening the development period. - ・Enables reproducible design based on factual data, rather than relying on experience and intuition.

- ・Evaluation under various conditions are available, making it possible to create products with no omissions in its specifications.

【Material and Structural Design】

- ・We are able to provide optimal material design with the know-how we have accumulated over the years based on our extensive knowledge and experience in vibration isolation and our vast array of material parameters.

- ・We can propose various solutions from a single component vibration dampers to vibration isolation trestles a complex designs that include peripheral components.

【Vibration measurement and Performance evaluation】

- ・Various measurements such as reproducibility tests, vibration measurements, and physical property evaluations can be performed.

We can flexibly respond to customer needs and provide total support for vibration isolation design by using the data obtained from these tests for vibration isolation simulation and material and structural design.

Service flow

Depending on the content of your consultation, we will respond flexibly and will propose a solution tailored to your needs.

Inquiry

Please contact us using this inquiry form.

Meeting (online)

Confirmation of the request and requirement

Our representative will contact you via email. We will hold a meeting (online) to review your concerns and specific requirements.

Setting Goals

Our engineer will be present at this phase to set a goal to be achieved in accordance with your request.

Detailed proposal of services

We will submit a proposal with specific service details to achieve your goals.

・Goals

・Proposal in details

・Items for which we ask for your cooperation

・Timeline

・Images of deliverables

Submission of the quote

We will provide a quotation for the proposed service.

Agreement on service details

Proposal is accepted and a contract (purchase order) is executed.

- Execution of services(We can flexibly arrange the service package. For example, the service can be partially selected and executed.)

-

Vibration test simulationMaterial and Structural DesignVibration measurement and Performance evaluation

- ①Provision of data (Customer)

- ②Analysis of the provided data and creation of models necessary for simulation (Taica)

- ③Perform simulation (Taica)

- ④Report simulation results and propose material/structural design based on the results (Taica)

- ⑤After discussion, determine material/structural design and submit drawings (Taica)

- ⑥Sample production and shipment (Taica)

- ⑦Feedback of evaluation results (Customer)

- ⑧Confirmation of target achievement (if NG, back to ③)

Example: "Vibration isolation simulation" + "Material and structual design"

Service completion

Deliverables will be provided to complete the project.

Follow-up service

We will continue to make appropriate proposals and follow-up after the completion of our Anti-vibration design assistance service, including additional requests and mass production support.

Notes

- *This service is intended to assist in the anti-vibration design and is not responsible for the final design or quality assurance of the customer's product.

- *Please note that the service contents may need to be changed due to unresolvable circumstances.

- 1)When there are additions or changes to the purpose or content of the services

- 2)When information necessary for the execution of Anti-vibration design assistance service is not provided

- 3)In the event of force majeure errors or malfunctions in software or hardware

- 4)When additional work is required after acceptance and inspection of deliverables

- *Any additional requirements beyond the previously agreed upon Anti-vibration design assistance service will be subject to separate consultation and quotation.

- *The customer is responsible for confirming the damping performance and the specifications of the deliverables.

- *Confidentiality of information handled by this service shall be stipulated in a separate Non-Disclosure Agreement (NDA).

For more information

Please contact us for more details using the inquiry form in the link below.

inquiry formテ

- Customization

- We also develop custom products to meet our customers’ individual needs. Contact us today!